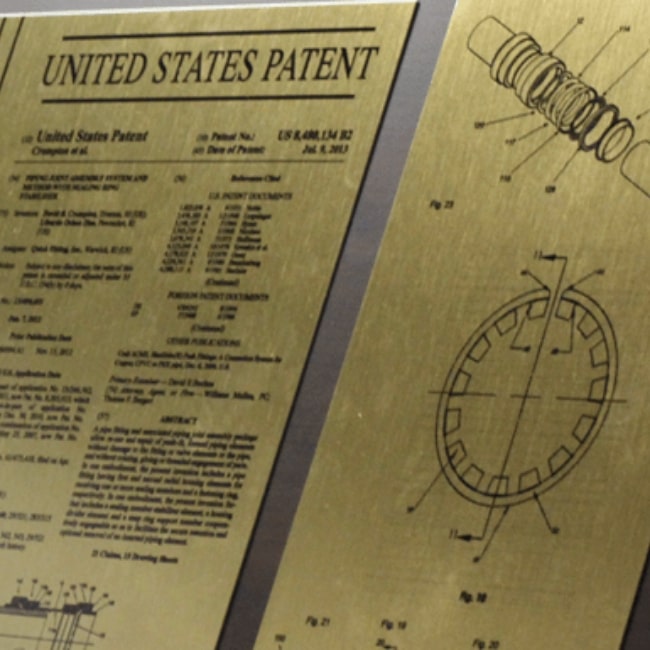

Our patented push fitting technologies offer a full-range of high-quality plumbing fittings and valves that are quick and easy to install.

Our repairable quick-connect fittings are backed by excellent customer support including training and consultation services, help lines and on-site assistance. To top it off, we offer the industry’s longest product warranty — 75 years!

For international inquiries, please click here